WHY SHOULD AN INTERIOR DOOR BE BEVELED?

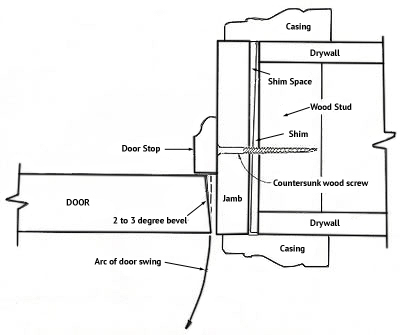

The first step in hanging a door into an existing jamb is to bevel the edge. Edge beveling is not absolutely mandatory but it is highly recommended because it makes for a high quality installation. Beveling a door is the process of shaping the leading edge of the door at an angle. The bevel is usually 2 to 3 degrees and is done the entire length of the door on the lock side. The reason for beveling is to allow for a tighter fit of the door to the jamb when in the closed position (see illustration below).

Note that many of our doors are supplied already factory beveled, usually on both sides for reversibility.

When a door swings open or closed there is a radius or arc created by the path of the door. When closing a non-beveled door the leading edge will be closer to the outside corner edge of the jamb than the trailing edge. By machining a bevel on the lockset side of the door both the leading edge and the trailing edge of the door will be the same distance away from the corner edge of the jamb when opening and closing the door. This allows for a tighter fit when the door is in the closed position.

1/8″ clearance is recommended between the edge of the door and the edge of the jamb when the door is in the closed position. Any closer than that and you could have problems during humid conditions when the door swells in width and any more than 1/8, the lockset bolt may not reach the strike plate during very dry conditions when the door shrinks in width.